In today’s competitive manufacturing landscape, Building Trust and Reliability with Quality Components has become the cornerstone of sustainable business relationships. When engineering firms and manufacturing companies select components for their projects, they’re not just purchasing parts—they’re investing in reliability, performance, and ultimately, their own reputation. This trust-based relationship between suppliers and manufacturers hinges on the consistent delivery of high-quality components that meet or exceed industry standards. Companies that understand this fundamental principle position themselves for long-term success by prioritizing quality at every step of their production process.

The importance of component quality in manufacturing

Quality components form the foundation of any well-engineered product. Whether you’re assembling industrial machinery, automotive parts, or specialized equipment, the reliability of your final product depends entirely on the integrity of each individual component. When manufacturers compromise on component quality, they introduce vulnerabilities that can lead to premature failures, safety hazards, and costly warranty claims. The ripple effects of using substandard parts extend far beyond immediate financial considerations—they can permanently damage your brand’s reputation and erode customer confidence.

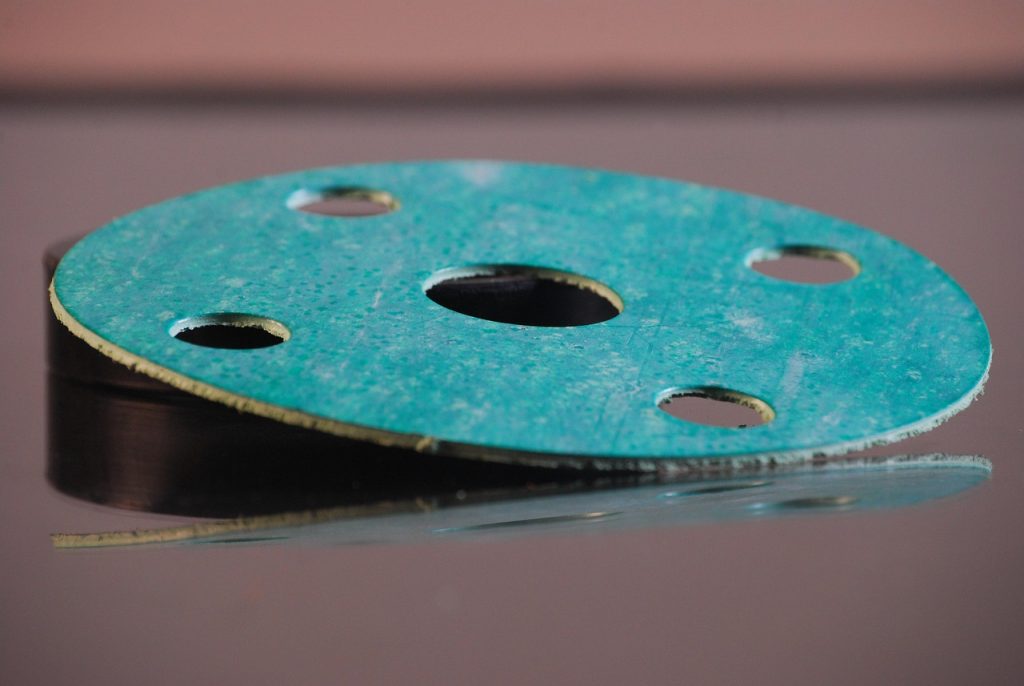

Expert manufacturers recognize that Building Trust and Reliability with Quality Components is not simply a marketing tagline but a comprehensive business philosophy. This approach requires rigorous material selection, precision engineering, and consistent quality control throughout the production process. For instance, when selecting a gasket material for high-temperature applications, manufacturers must consider not only immediate performance characteristics but also long-term reliability under thermal cycling and chemical exposure. This level of attention to detail demonstrates the expertise and commitment that builds lasting trust with clients.

Material selection as a foundation of quality

The journey toward component reliability begins with material selection. Different applications demand specific material properties, and choosing the right foundation for your components requires both technical knowledge and practical experience. Take mica gasket material as an example—this specialized material offers exceptional thermal resistance and electrical insulation properties, making it ideal for high-temperature sealing applications in power generation, aerospace, and industrial heating systems. However, proper implementation requires understanding its compression characteristics, thickness tolerances, and compatibility with mating surfaces.

Professional manufacturers employ materials engineers who analyze application requirements and select appropriate materials based on scientific principles rather than merely cost considerations. This expertise becomes particularly evident when dealing with specialized components such as high-temperature gaskets, where the wrong material selection can lead to catastrophic failures. By partnering with suppliers who demonstrate this level of material knowledge, you gain access to components designed specifically for your application requirements rather than generic solutions that may fall short under real-world conditions.

Manufacturing processes that ensure consistency

Even with the best materials, inadequate manufacturing processes can introduce variations that compromise component reliability. Establishing consistent, repeatable production methods represents a critical step in Building Trust and Reliability with Quality Components. This consistency requires documented procedures, properly calibrated equipment, and trained personnel who understand the importance of adhering to established specifications.

The pro don approach to manufacturing emphasizes prevention rather than detection—designing quality into the process rather than inspecting it afterward. This methodology incorporates statistical process control, error-proofing techniques, and regular audits to maintain consistency across production runs. For example, when manufacturing precision gaskets, this might include automated cutting systems with optical verification, material testing at multiple production stages, and documented traceability from raw material to finished component. These systems create a foundation of reliability that customers can trust, knowing that each component will perform as expected regardless of when it was manufactured.

Quality control as verification of excellence

While prevention-focused manufacturing remains the primary approach to quality, verification through appropriate testing provides essential confirmation that components meet all specified requirements. Comprehensive quality control programs incorporate both in-process checks and final validation testing that simulates real-world conditions. For specialized products like mica gasket material, this might include thermal cycling tests, compression set measurements, and chemical resistance validation to ensure performance under the most demanding conditions.

Customers increasingly expect transparency in quality control processes, including access to material certifications, dimensional inspection reports, and performance test results. By providing this documentation, manufacturers demonstrate their commitment to quality while giving customers confidence in the components they’re purchasing. This transparency builds trust by showing that you have nothing to hide and stand behind the quality of your products with verifiable evidence rather than empty promises.

The competitive advantage of quality components

In today’s global marketplace, where customers can source components from virtually anywhere, quality becomes a powerful differentiator that justifies premium pricing and builds lasting relationships. Manufacturers who invest in Building Trust and Reliability with Quality Components create a competitive advantage that transcends short-term price considerations. When your components consistently perform as expected, customers recognize the value in reduced downtime, fewer warranty claims, and enhanced end-product reliability.

This quality-focused approach creates a virtuous cycle: reliable components lead to satisfied customers, who then provide positive references and repeat business, enabling further investment in quality improvements. Conversely, manufacturers who compromise on quality to reduce costs often find themselves trapped in a downward spiral of customer complaints, warranty costs, and damaged reputation that becomes increasingly difficult to escape.

Developing lasting partnerships through reliability

The ultimate goal of Building Trust and Reliability with Quality Components extends beyond individual transactions to establish lasting partnerships between component suppliers and their customers. These relationships thrive on consistent performance, open communication, and mutual respect. When you provide components that consistently meet or exceed expectations, customers come to view you as an extension of their own operations rather than merely a vendor.

These partnerships create opportunities for collaborative problem-solving, where your expertise in materials and manufacturing processes helps customers overcome design challenges and optimize their products. Whether you’re recommending the ideal gasket material for a challenging sealing application or suggesting design modifications to enhance manufacturability, these interactions demonstrate your commitment to customer success rather than simply filling orders. The trust developed through these interactions creates a foundation for long-term business relationships that weather economic fluctuations and market changes.

By prioritizing quality throughout your organization, from material selection through manufacturing and quality control, you establish your company as a trusted supplier of reliable components. This reputation for excellence becomes your most valuable asset, attracting quality-conscious customers and allowing you to focus on value rather than competing solely on price. In manufacturing, as in most aspects of business, trust and reliability ultimately prove more profitable than short-term cost-cutting measures that compromise quality.