Manufacturing processes for industrial gaskets have undergone a remarkable transformation with the advent of laser cutting gaskets technology. For decades, traditional die-cutting methods dominated the industry, imposing substantial tooling costs and lengthy setup times on manufacturers. Prior to laser cutting gaskets becoming mainstream, each new gasket design required creating custom dies, inevitably leading to production delays and escalating expenses. The precision of these conventional methods faced significant limitations, particularly when fabricating complex geometries or working with specialized materials like PTFE (polytetrafluoroethylene). Laser cutting gaskets technology addressed these longstanding challenges by eliminating the need for physical tooling while delivering superior precision and flexibility across diverse material applications.

Precision and Efficiency: Laser Cutting Technology

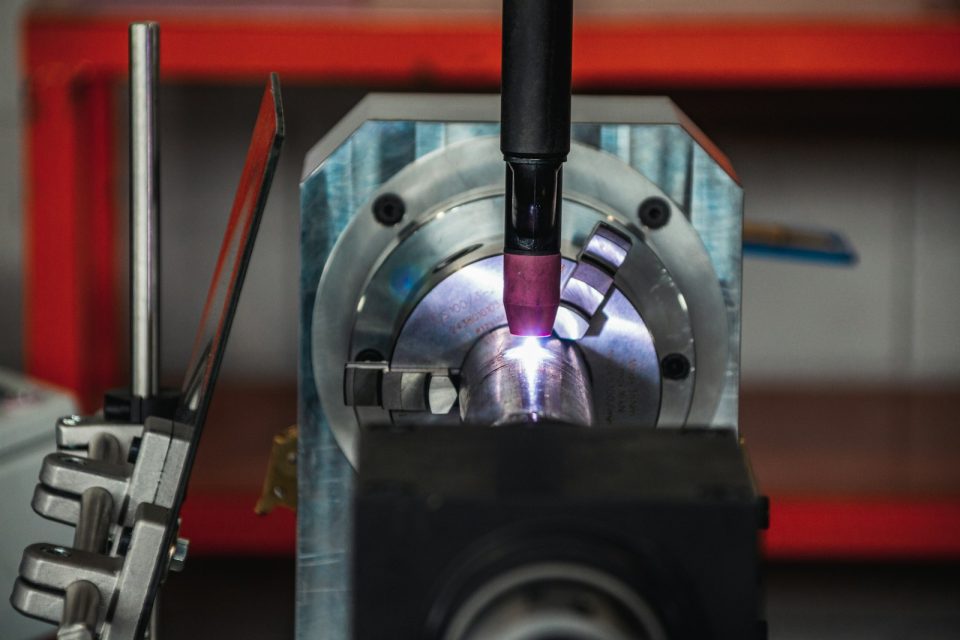

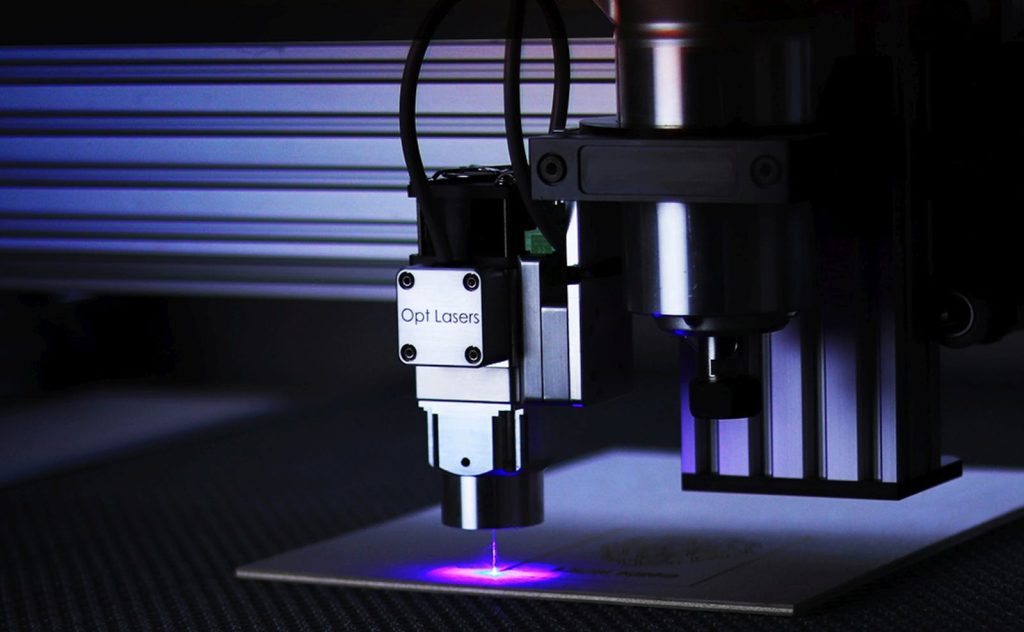

The introduction of laser cutting gaskets marked a pivotal shift in production capabilities. Unlike conventional methods, laser cutting utilizes concentrated light beams to create precise cuts without physical contact with materials. This technology achieves tolerances as tight as ±0.05mm, significantly surpassing the capabilities of traditional die-cutting methods. For manufacturers, this precision translates to gaskets that provide superior sealing performance in critical applications.

Modern laser systems can process materials at speeds up to 100 meters per minute, dramatically reducing production time compared to conventional methods. The non-contact nature of laser cutting eliminates tool wear issues, ensuring consistent quality throughout production runs regardless of volume.

PTFE Gaskets: Material Properties and Applications

PTFE gaskets have become increasingly important in various industries due to their exceptional chemical resistance and temperature stability. These gaskets maintain integrity in environments ranging from -268°C to 260°C, making them ideal for extreme applications. Their non-stick properties and resistance to nearly all chemicals make PTFE gaskets essential in pharmaceutical, chemical processing, and food production facilities.

When manufacturing PTFE gaskets, traditional cutting methods often created challenges:

- Material deformation during cutting

- Imprecise edge quality

- Limited ability to create complex geometries

- Material waste due to cutting limitations

Laser cutting addressed these challenges by providing clean, precise cuts without deformation, even when working with thin PTFE sheets. The technology’s ability to handle complex designs opened new possibilities for gasket applications in specialized equipment.

Cost and Time Savings in Production Lines

Implementing laser cutting gaskets technology in production environments delivers measurable economic benefits. Companies typically report:

- 40-60% reduction in material waste

- 70% decrease in production lead times for custom gaskets

- 30-50% lower production costs for small to medium batch sizes

- Elimination of tooling costs for new designs

The digital workflow associated with laser cutting enables just-in-time manufacturing practices. Production facilities can maintain minimal inventory while retaining the ability to quickly produce exact quantities as needed. This flexibility has transformed supply chain management for both gasket manufacturers and their industrial clients.

Quality Control Improvements

The integration of laser cutting technology with digital quality control systems has significantly improved production consistency. Modern laser cutting systems incorporate vision systems that perform real-time inspection of each gasket, ensuring dimensional accuracy and material integrity. This automated inspection process catches defects that might otherwise go undetected until final assembly.

For PTFE gaskets and other critical sealing components, this level of quality assurance is particularly valuable. The non-contact nature of laser processing prevents contamination issues that can occur with traditional cutting methods, an essential consideration for gaskets used in clean room environments or medical applications.

Industry-Specific Applications

The aerospace industry was among the first to embrace laser cutting gaskets technology, particularly for PTFE gaskets used in fuel systems and hydraulic applications. The ability to create precise, consistent parts with minimal material waste justified the initial investment in laser technology.

The semiconductor manufacturing sector similarly benefited from laser-cut gaskets. The extreme cleanliness requirements and precise tolerances necessary for semiconductor processing equipment made laser cutting the preferred production method. PTFE gaskets are commonly used in these applications due to their chemical resistance and purity.

Automotive manufacturers have incorporated laser cutting into production lines for gaskets used in engines, transmissions, and fuel systems. The ability to rapidly iterate designs during development and then transition seamlessly to mass production has accelerated innovation cycles.

Future Innovations in Laser Cutting Technology

Emerging developments in laser technology continue to expand the capabilities of laser cutting gaskets manufacturing. Multi-beam systems now enable simultaneous cutting of multiple gaskets, further increasing production efficiency. Advances in beam control allow for micro-cutting of gaskets with features measuring just fractions of a millimeter, opening new possibilities for miniaturized components.

For PTFE gaskets and other specialized materials, manufacturers are developing hybrid systems that combine laser cutting with other processing methods. These integrated systems can perform cutting, surface treatment, and marking in a single operation, further streamlining production.

The digital integration of laser cutting systems with enterprise resource planning and supply chain management software is creating smart factories capable of responding to demand fluctuations in real-time. This connectivity supports the ongoing transformation toward more agile and responsive manufacturing operations across industries that rely on precision gaskets for their products.